What an Amazon FBA specialist is (and isn’t)

An Amazon FBA specialist is a person (or role) focused on running the day-to-day operations of an Amazon FBA business inside Seller Central—so inventory, inbound shipments, and operational follow-through don’t become constant emergencies. They are not “FBA itself,” and they’re not automatically the same as a PPC or listing specialist.

| If you hire an ops-focused FBA specialist… | Expect this | Don’t expect this |

|---|---|---|

| Core focus | Inventory health, inbound shipment coordination, issue resolution, reporting cadence | Guaranteed sales, rankings, or “account safety” promises |

| Where they work | Mostly in Seller Central + your internal trackers/SOPs | “Magic fixes” without documented process |

| How they help | Prevent stockouts and inbound confusion through planning + follow-through | Customs outcomes “guaranteed” or policy certainty without verification |

Key points to keep you from hiring the wrong “specialist”:

- Scope matters more than the title. “Amazon specialist” can mean ops, PPC, listings, or a generalist VA.

- Outputs beat opinions. A good ops specialist produces clear deliverables (status, action list, exceptions log), not vague reassurance.

- They coordinate; they don’t physically touch cartons. Physical prep/shipping is usually handled by a prep center or freight forwarder.

Boundary conditions:

- If you’re early-stage (few SKUs, stable replenishment), you may only need lightweight ops support.

- If you source from multiple suppliers, the role expands because coordination load increases.

FBA vs an FBA specialist: who does what?

FBA (Fulfillment by Amazon) is the fulfillment program; an FBA specialist is a person/role that helps you operate around that program. Once you split “who owns what,” you can define scope, hire smarter, and prevent handoff mistakes.

A practical responsibility split (high-level):

| Category | Amazon (FBA program) | You (the seller/brand) | FBA specialist (ops role) | Prep center / freight forwarder / 3PL |

|---|---|---|---|---|

| Fulfillment execution | Stores eligible inventory, picks/packs/ships orders, handles customer service/returns for FBA orders (per Amazon’s program descriptions) | Decides what to send, when, and which SKUs to replenish | Tracks inventory health, flags risks, coordinates replenishment timing | Physically receives goods, preps/labels, consolidates, ships to Amazon or your warehouse |

| Product & compliance ownership | Sets marketplace requirements and program rules (subject to change) | Owns product compliance decisions, documents, brand/IP, and product safety obligations | Helps organize info and follow SOPs; does not replace professional advice | Executes only what’s supplied; may help check for obvious prep/label issues |

| Inbound planning | Provides tools/workflows for inbound shipment creation in Seller Central | Chooses strategy (ship method, schedule, packaging approach) | Builds/maintains inbound plans and exception tracking | Executes pack-out, labeling, booking, delivery coordination |

| Problem resolution | Provides case systems and operational status signals | Owns escalation decisions and risk tolerance | Opens/updates cases, documents issues, drives follow-through | Supplies photos/receiving data; fixes prep issues when agreed |

If you want an official starting point for what “FBA” refers to, see Amazon’s overview page:

https://sell.amazon.com/fulfillment-by-amazon

Boundary conditions:

- Amazon workflows and terminology evolve; verify current details in Seller Central and official documentation.

- Your partner stack changes the split (factory-direct shipping vs consolidation-first workflows).

Scope boundaries: what a good ops-focused FBA specialist owns

A good ops-focused Amazon FBA specialist owns the operational system (planning, tracking, follow-through)—not “growth outcomes” like guaranteed sales. The goal is to reduce confusion by defining what they are accountable for and what they should coordinate with other specialists.

In-scope (ops-focused)

- Inventory health monitoring (stockout risk, inbound status, exception tracking)

- Inbound shipment planning and coordination (what needs to be sent, when, and what information partners need)

- Seller Central operational follow-through (case management, documentation, process compliance)

- Reporting cadence and “next actions” (what changed, what’s blocked, what needs approval)

- SOP maintenance (how your team prevents repeat mistakes)

Out-of-scope (or needs separate ownership)

- PPC strategy and daily bid management (often a separate PPC specialist)

- Listing copywriting/creative production (often listing/content specialist)

- Legal/tax “final answers” (should be handled by qualified professionals)

- Guarantees: sales, rankings, “no suspensions,” “no customs holds,” “always on-time delivery”

A simple comparison (helpful when hiring):

| Option | Best for | Typical risk | How to reduce the risk |

|---|---|---|---|

| Generalist VA | Low-complexity admin help, basic coordination | Vague scope, limited ops judgment | Define deliverables + escalation rules |

| Ops-focused FBA specialist | Inventory + inbound + operational follow-through | Overreach into PPC/listings, over-permissions | Role taxonomy + least-privilege access |

| Agency (mixed services) | Larger teams wanting bundled support | Blurred accountability, “black box” execution | Assign one owner for ops deliverables + reporting |

| Specialist stack (ops + PPC + listings) | Higher complexity, separation of duties | Coordination overhead | RACI + shared dashboards + clear handoffs |

Boundary conditions:

- Titles are inconsistent; define the role by deliverables and decision rights, not by “Amazon specialist” labels.

- One person can cover multiple areas only if the scope is explicitly limited and documented.

Ops vs listings vs PPC: a simple role taxonomy

Most “FBA specialist” hiring mistakes happen because people mix ops work with listing and ad work. A simple taxonomy helps you match the right hire to the problem you’re actually facing.

| Role | Primary goal | Typical tools | Good deliverables | Common failure mode |

|---|---|---|---|---|

| Ops-focused FBA specialist | Prevent stockouts and inbound chaos | Seller Central, inventory trackers, SOPs, case log | Inventory watchlist, inbound status, exception log, weekly action list | “Busy but not measurable” (no clear outputs) |

| Listing/content specialist | Improve listing quality and conversion | Listing editor, keyword tools, creative workflow | Updated listings, image/copy brief, content QA checklist | “Pretty listings” without operational alignment (wrong variations, mismatched SKUs) |

| PPC specialist | Manage ad efficiency and scale | Ads console, reporting dashboards | Campaign changes + performance notes + tests | “Chasing ROAS” while ops causes stockouts |

Boundary conditions:

- If one person covers multiple roles, force clarity: what is primary, what is secondary, and what is out of scope.

Day-to-day responsibilities and deliverables (what “good” looks like)

A strong Amazon FBA ops specialist is measurable because their work produces predictable outputs: what’s at risk, what’s changing, and what needs a decision. The day-to-day isn’t “doing everything”—it’s keeping inventory and inbound execution on track.

A practical day-to-day mini-table:

| Task | Where it happens | Output you can review |

|---|---|---|

| Monitor inventory health | Seller Central + internal tracker | Stockout-risk list + proposed replenishment actions |

| Track inbound shipments | Seller Central + partner updates | Inbound status summary + exception list |

| Prepare inbound plans | Seller Central workflow + SOP | Shipment plan notes + required handoff artifacts to partners |

| Resolve operational issues | Case system + documentation | Case log with status, evidence, and next steps |

| Maintain operational SOP | Shared docs | Updated checklist + “what changed and why” notes |

| Weekly ops review | Meeting + dashboard | Weekly action list with owners + deadlines |

Key points:

- A specialist’s value is in follow-through: turning signals into actions, and actions into closed loops.

- “Responsibility” should be written as outputs (what you can see) rather than “tasks” (what you hope happened).

- If you’re using a prep center/forwarder, day-to-day ops includes handoff accuracy (labels/carton plan data is correct and current).

Boundary conditions:

- Day-to-day tasks differ if you run FBA-only vs hybrid, or if you ship factory-direct vs consolidate first.

- Deliverables should match your replenishment cadence and team size; don’t overload a role with unnecessary reporting.

A “minimum viable deliverables” checklist you can ask for

If you want accountability without micromanaging, ask for a small set of deliverables that make ops visible. You can expand this after a short pilot.

Minimum viable deliverables (ops-focused):

- Weekly Inventory watchlist: what’s at risk, why, and proposed actions

- Weekly Inbound status summary: what’s in transit/processing and what’s blocked

- Weekly Action list: tasks, owners, deadlines, and escalations needed

- Ongoing Exception log: label/carton mismatches, shipment plan changes, missing info, delays

- Case log (if applicable): what’s open, evidence attached, next follow-up time

- Change log: what settings/processes changed and why (prevents silent breakage)

Boundary conditions:

- Start small; expand deliverables only after you see consistent follow-through.

Do you need one? A simple decision framework (and when it’s overkill)

You usually need an ops-focused FBA specialist when coordination load exceeds your team’s bandwidth—and the cost of mistakes (stockouts, inbound confusion, rework) starts recurring. If your operation is simple and stable, a full-time specialist can be overkill.

A simple decision tree (use the first “yes” that matches your situation):

- If you regularly stock out (or your inbound plan is always reactive) → you likely need ops support.

- If you source from multiple suppliers and cartons/labels are frequently mismatched → you likely need an ops owner for coordination and handoffs.

- If inbound shipments stall because nobody owns follow-through (cases, missing info, unclear responsibilities) → you likely need an ops specialist.

- If you have few SKUs and stable replenishment and you can run weekly ops checks yourself → a generalist VA or part-time ops support may be enough.

- If you already have a strong prep/forwarder partner that handles execution cleanly → your “specialist” scope can narrow to planning, tracking, and Seller Central follow-through.

A quick option comparison:

| Your situation | Best next step |

|---|---|

| Low complexity, stable replenishment | DIY + lightweight admin support |

| Medium complexity, recurring inbound issues | Part-time ops specialist + clear deliverables |

| High complexity, multi-supplier, frequent exceptions | Ops specialist (owner) + documented RACI + strong execution partners |

Boundary conditions:

- “Need” is driven by complexity and risk, not revenue alone.

- If you can’t define scope and deliverables, hiring any “specialist” is risky—fix scope first.

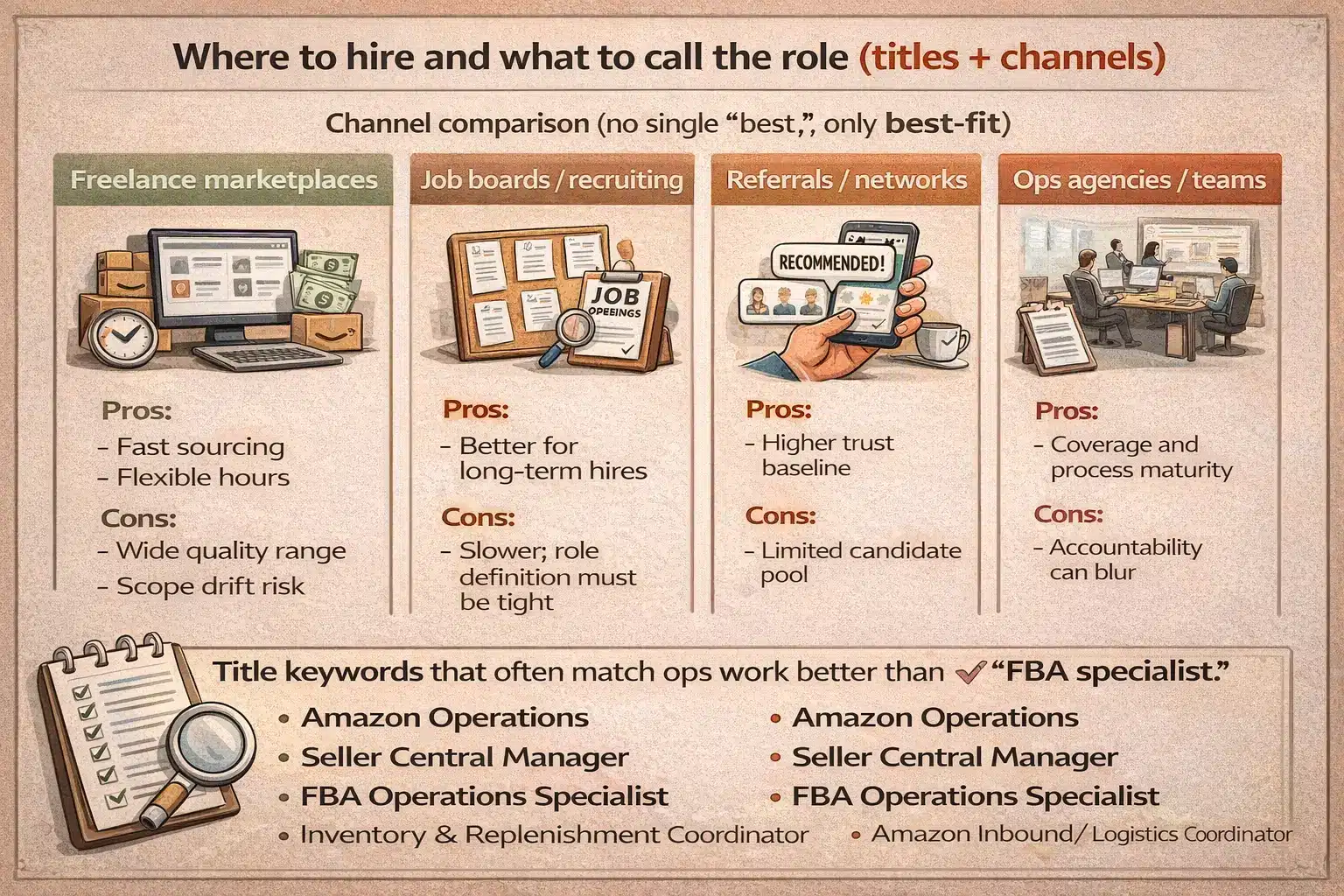

Where to hire and what to call the role (titles + channels)

You can hire an ops-focused FBA specialist through multiple channels, but the real lever is using titles and deliverables that match the work. If you only search “Amazon specialist,” you’ll get a mix of PPC, listings, and generalists.

Channel comparison (no single “best,” only best-fit):

| Channel | Pros | Cons | Best for |

|---|---|---|---|

| Freelance marketplaces | Fast sourcing, flexible hours | Wide quality range, scope drift risk | Part-time ops support with clear SOP |

| Job boards / recruiting | Better for long-term hires | Slower; role definition must be tight | In-house ops owner |

| Referrals / networks | Higher trust baseline | Limited candidate pool | Experienced sellers scaling complexity |

| Ops agencies / teams | Coverage and process maturity | Accountability can blur | Sellers who want a managed ops function |

Title keywords that often match ops work better than “FBA specialist”:

- “Amazon Operations”

- “Seller Central Manager”

- “FBA Operations Specialist”

- “Inventory & Replenishment Coordinator”

- “Amazon Inbound / Logistics Coordinator”

Job-post checklist (scope-first):

- What systems they will touch (Seller Central, trackers, partner comms)

- Required deliverables (inventory watchlist, inbound status, action list, exception log)

- What is explicitly out of scope (PPC, creative, legal/tax decisions)

- Access rules (least privilege first, no shared passwords)

- Communication cadence (weekly review + escalation expectations)

Boundary conditions:

- The “best” channel depends on how much onboarding and SOP you can provide; clearer SOPs widen your hiring options.

How to vet candidates before you hand over Seller Central access

You reduce hiring risk by vetting for operational thinking and documented follow-through, not just “Amazon familiarity.” A safe vetting process forces candidates to show how they work before they get meaningful access.

A step-by-step vetting flow:

- Screen for scope fit

- Ask what they consider in-scope vs out-of-scope (listen for clarity, not confidence).

- Ask for ops proof (anonymized)

- Examples: weekly ops report, exception log, a case-resolution write-up, or SOP excerpts.

- Run a task-based test

- Give a controlled scenario: “We have 3 SKUs at risk + 2 inbound shipments delayed—write the next-week action plan and what info you need.”

- Check how they handle handoffs

- Ask: “What do you send to a prep center/forwarder to prevent label/carton mistakes?”

- Pilot with limited scope

- Start with read-only or limited permissions and a narrow deliverables set for 2–4 weeks.

- Expand only after reliability

- Increase permissions and scope only after you see consistent documentation and follow-through.

Interview prompts that reveal ops competence:

- “Walk me through how you prevent stockouts—what signals do you track and what actions do you take?”

- “When an inbound shipment plan changes, what do you update and who do you notify?”

- “Show me how you document decisions and exceptions so nothing gets lost.”

Boundary conditions:

- If they will touch shipment settings or inventory-related actions, vetting should be stricter and the pilot should be longer.

- A good candidate will welcome clarity; resistance to documentation is a warning sign.

Red flags table: what to watch for (and safer alternatives)

Red flags are most useful when they translate into action: tighten scope, reduce access, or move on.

| Red flag | Why it matters | Safer alternative |

|---|---|---|

| Promises “guaranteed sales/rankings” | Outcomes aren’t fully controllable and signals hype | Ask for deliverables and process, not promises |

| Demands full admin access immediately | Over-permission increases irreversible risk | Start least-privilege + pilot; expand gradually |

| Won’t document changes | Silent changes break ops over time | Require change log + weekly ops review |

| Vague reporting (“I’ll manage it”) | You can’t measure effectiveness | Require inventory watchlist + action list + exception log |

| Blurs PPC/listings/ops without boundaries | Role overload leads to missed basics | Use the role taxonomy and split ownership |

| Avoids discussing mistakes | Ops is about prevention and recovery | Ask for a past failure and how they fixed it |

Boundary conditions:

- One red flag alone may not disqualify; consistent patterns often do.

Seller Central access: minimum safe permissions and how to grant them

The safest way to give an FBA specialist access is to avoid shared logins and use role-based permissions so you can audit and revoke access cleanly. Start with the minimum needed for the pilot, then expand only when the scope truly requires it.

A safe access setup (high-level):

- Create a dedicated user (do not share the primary login).

- Assign least-privilege permissions for the pilot scope (start small).

- Enable strong authentication on every account used.

- Define what they should never access (billing/payment methods, bank details, or anything unrelated to the agreed scope).

- Review access on a schedule (weekly during the pilot; remove access immediately when scope ends).

A “permission risk” mini-matrix (conceptual):

| Permission level | What it enables | When to grant | Risk level |

|---|---|---|---|

| Read-only / reporting | Viewing data and performance signals | Early pilot | Low |

| Ops support | Creating drafts, preparing notes, managing routine follow-ups | After proof of process | Medium |

| Shipment/inventory actions | Changing inbound/shipment-related settings and workflows | Only if role explicitly owns this | Higher |

| Admin-like access | Broad settings/control | Rarely justified | Highest |

Where to verify current access mechanics:

Seller Central Help Hub (search within Seller Central for “user permissions”): https://sellercentral.amazon.com/help/hub

Boundary conditions:

- Permission options vary by account configuration and region; verify current settings inside Seller Central.

- If a role needs higher-risk permissions, require stronger documentation and a longer pilot.

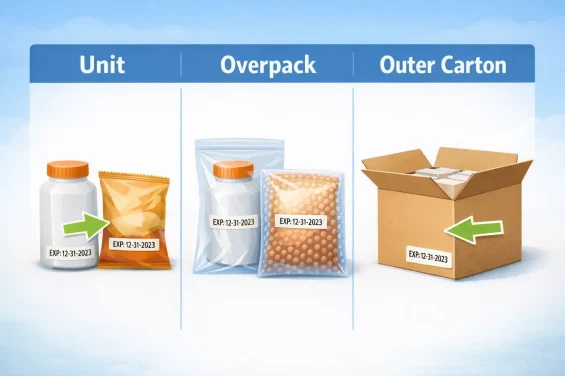

Specialist vs prep center vs freight forwarder: how to split the work

Most inbound problems happen at handoffs: the shipment plan says one thing, but cartons/labels reflect another. You reduce that risk by splitting ownership clearly: the specialist owns planning and coordination, while a prep/forwarder owns physical receiving, prep, and delivery execution.

A simple workflow (planning → execution):

- Plan (specialist + seller): decide what to send, when, and what constraints apply

- Prep (prep center / China warehouse / partner): receive, inspect, label, pack, and confirm carton plan

- Ship (forwarder / carrier): book transport, manage documentation, deliver to destination

- Reconcile (specialist): track status, resolve exceptions, update plans, document outcomes

A practical RACI-style split:

| Work item | Seller/brand | FBA ops specialist | Prep center / warehouse | Freight forwarder |

|---|---|---|---|---|

| SKU list and quantities | A | R (maintain & track) | C | C |

| Label files and labeling rules | A | R (coordinate + verify handoff) | R (apply + photo/confirm) | C |

| Carton plan (contents by carton) | A | R (own the plan + version control) | R (pack-out to plan + confirm) | C |

| Shipment plan accuracy (data) | A | R | C | C |

| Physical pack-out accuracy | C | C | R | C |

| Booking and transport execution | C | C | C | R |

Boundary conditions:

- The split changes if you consolidate in China vs ship factory-direct from each supplier.

- Shipment method (parcel vs palletized freight) changes how detailed your carton/pallet planning needs to be.

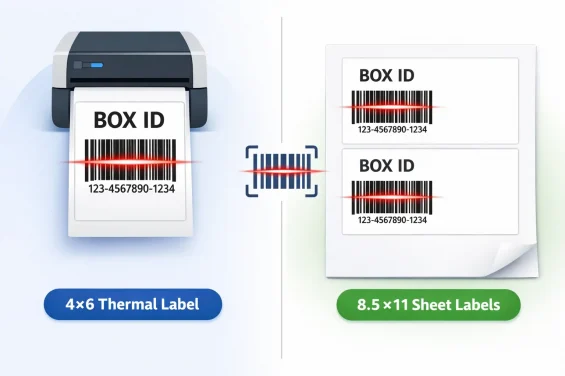

The handoff checklist: what your specialist should send your prep/forwarder

A clean handoff is a set of explicit artifacts (files/data + version control), not a vague message like “please ship these.” If your operation struggles with inbound errors, this checklist is often the fastest improvement.

Handoff checklist (inputs to partners):

- SKU list + quantities (and what changed since last version)

- Label files (item labels, carton labels) and labeling rules

- Carton plan (what’s inside each carton; versioned)

- Packaging instructions (polybag, bubble wrap, inserts, bundle rules if any)

- Ship window / priority notes (what must leave first and why)

- Destination details (destination type and any constraints you’re aware of)

- Exception rules (what the partner should do if something doesn’t match: stop, photo, escalate)

- Owner contacts + escalation path (who can approve changes quickly)

Boundary conditions:

- Requirements differ by shipment type and destination constraints; keep a “core checklist” and add shipment-specific fields as needed.

A simple RACI: who owns labels, carton plan, and shipment-plan accuracy?

RACI is useful because it forces one “Responsible” owner for each failure-prone item. Without it, inbound issues become blame loops instead of fixable processes.

A simple RACI you can copy into a shared doc:

| Item | Responsible (does the work) | Accountable (final owner) | Consulted | Informed |

|---|---|---|---|---|

| Create/update carton plan | Ops specialist | Seller/brand | Prep/warehouse | Forwarder |

| Apply labels to cartons | Prep/warehouse | Seller/brand | Ops specialist | Forwarder |

| Verify label/carton match (spot checks) | Prep/warehouse | Ops specialist (process owner) | Seller/brand | Forwarder |

| Track inbound status + exceptions | Ops specialist | Seller/brand | Forwarder | Prep/warehouse |

| Approve changes when mismatches occur | Seller/brand | Seller/brand | Ops specialist + prep | Forwarder |

Boundary conditions:

- Ownership can shift by partner; write it down per shipment type so the team doesn’t “guess” under pressure.

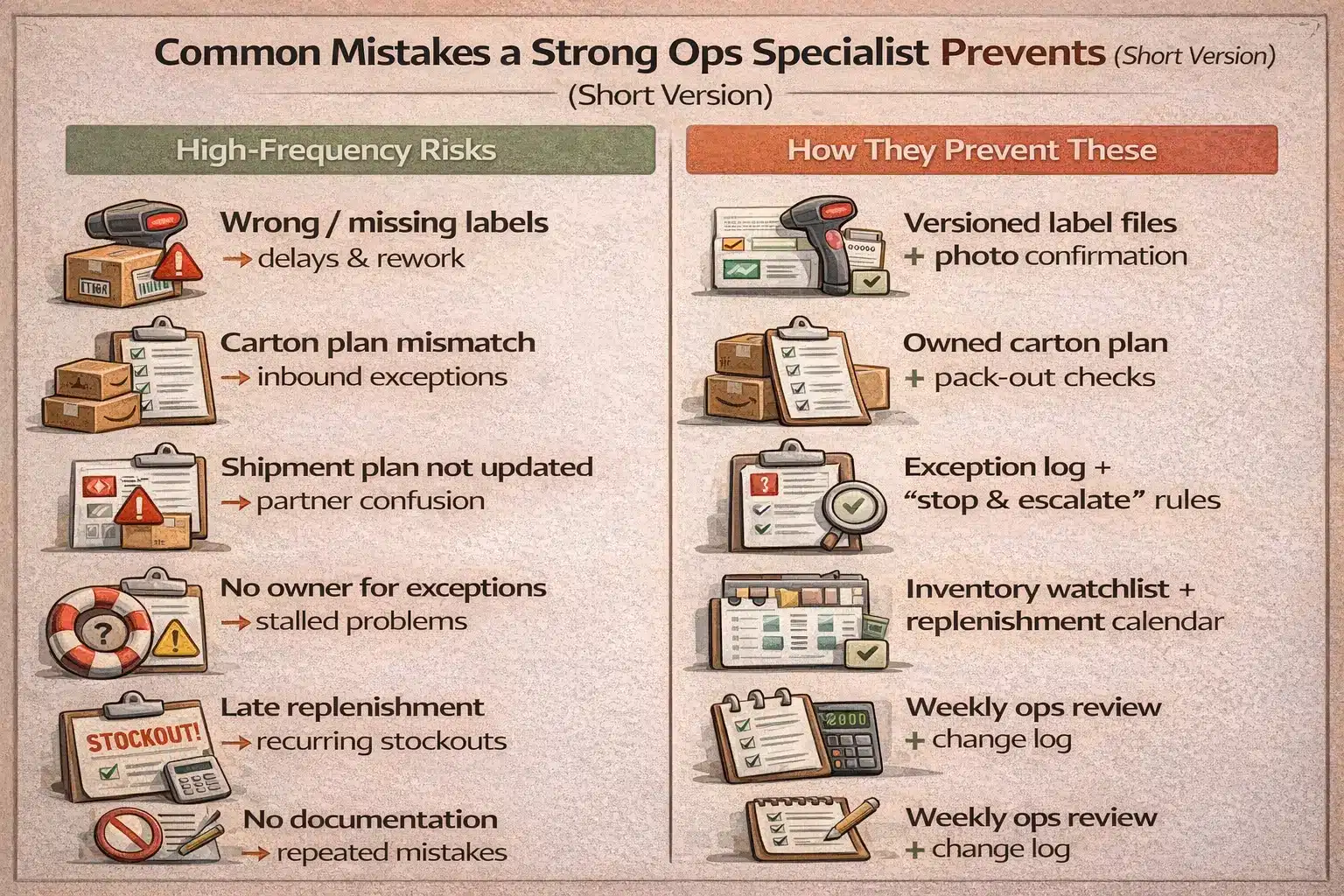

Common mistakes a strong ops specialist prevents (risk checklist)

Ops excellence is mostly mistake prevention: catching predictable failure points early and closing loops when exceptions happen. The best specialists don’t eliminate risk—but they reduce preventable chaos.

Risk checklist (high-frequency):

- Label files sent late, wrong version, or applied inconsistently

- Carton plan not aligned with what was actually packed

- Shipment plan changes not communicated to execution partners

- No single owner for “exceptions,” so problems stall

- Replenishment planned too late, leading to recurring stockouts

- Documentation scattered (no case log / no change log)

Mistake → impact → prevention (qualitative):

| Mistake | Typical impact | Prevention habit |

|---|---|---|

| Wrong/missing labels | Delays, rework, receiving confusion | Versioned label file handoff + photo confirmation |

| Carton contents mismatch | Inbound exceptions and slow reconciliation | Carton plan ownership + pack-out confirmation checks |

| Shipment plan vs reality mismatch | Status confusion and follow-up workload | Exception log + “stop and escalate” rules |

| Stockout-driven chaos | Lost momentum and reactive shipping | Inventory watchlist + replenishment calendar |

| No documented decisions | Repeat mistakes | Weekly ops review + change log |

Boundary conditions:

- Avoid turning this into a blame list; the goal is to add checks where ownership changes hands.

How FBA specialists charge (and how to compare offers safely)

Most FBA specialists charge in one of three ways (hourly, retainer, or project), but the safest comparison is always “scope + deliverables + access boundaries.” If you compare on price alone, you tend to buy ambiguity.

Pricing model comparison (structure-only):

| Model | Best for | Watch-outs | How to compare safely |

|---|---|---|---|

| Hourly | Ad hoc ops help and cleanup | Incentive to stay reactive | Set deliverables and a weekly ops review |

| Monthly retainer | Ongoing ops ownership | Scope creep if undefined | Define outputs (watchlist, inbound status, exception log) |

| Project-based | Setup/SOP creation or a defined transition | Handoffs after project ends | Require documentation + training + change log |

Warning signs (pricing-related):

- Outcome guarantees (“we’ll guarantee sales/ROI/zero issues”)

- No written deliverables, only “we manage everything”

- Push for broad access without a pilot

Boundary conditions:

- Pricing varies widely by scope (ops-only vs ops+PPC+listings). Compare like-for-like scope and deliverables.

FAQ

Q: What is an Amazon FBA specialist?

A: An Amazon FBA specialist is a person or role that helps operate an Amazon FBA business—typically by tracking inventory health, coordinating inbound shipments, and driving operational follow-through in Seller Central. The key is scope: some “Amazon specialists” focus on ads or listings, so define deliverables and boundaries before you hire.

Q: Is an Amazon FBA specialist the same as Fulfillment by Amazon (FBA)?

A: No. FBA is Amazon’s fulfillment program, while an FBA specialist is a human role that helps you operate around that program—planning replenishment, tracking inbound status, handling exceptions, and coordinating partners. A clean responsibility split (Amazon vs seller vs specialist vs partners) prevents scope confusion and inbound mistakes.

Q: What does FBA mean in Amazon?

A: FBA stands for Fulfillment by Amazon. In general terms, it refers to Amazon storing your inventory and fulfilling eligible orders (pick/pack/ship) and handling customer service and returns for those FBA orders, as described in Amazon’s program overviews. Details can vary by marketplace and can change, so verify current requirements in official documentation.

Q: What does an Amazon FBA specialist do?

A: In an ops-focused scope, they monitor inventory risk, coordinate inbound shipments, maintain an exception log, and keep operations measurable through recurring deliverables (action list, inbound status, watchlist). They may also manage routine Seller Central follow-ups. They typically do not replace PPC or listing specialists unless scope is explicitly combined.

Q: Do I need an FBA specialist or a prep center/freight forwarder?

A: They solve different problems. A prep center or forwarder executes physical work (receiving, labeling, packing, shipping). An ops-focused specialist owns planning, tracking, and follow-through (especially the handoffs and exceptions). If inbound mistakes repeat, you often need both: execution capacity plus a single owner for coordination and documentation.

Q: How do you vet an Amazon FBA specialist before giving Seller Central access?

A: Vet for process and outputs: ask for anonymized ops deliverables (watchlist, exception log), run a scenario test (“write the next-week action plan”), and start with a limited-scope pilot using least-privilege access. Expand responsibilities only after you see consistent documentation, clear escalation habits, and reliable follow-through.

Q: What are red flags when hiring an Amazon FBA specialist?

A: Red flags include guaranteed outcome claims, refusal to document changes, pushing for admin access immediately, vague reporting (“I’ll manage everything”), and mixing PPC/listings/ops without clear boundaries. Safer signals include willingness to define deliverables, comfort with a pilot, and a consistent habit of logging exceptions and decisions.

Summary and next steps

If you remember only three things, make them these: define scope by deliverables, grant access with least privilege, and split planning vs execution ownership so handoffs don’t break. That combination prevents most “FBA chaos” problems before they become expensive.

A practical next-step checklist:

- Write a one-page scope: in-scope, out-of-scope, weekly deliverables, escalation rules.

- Add a pilot plan: 2–4 weeks, limited permissions, and a simple ops review cadence.

- Build a handoff checklist + RACI for labels, carton plans, and exception handling.

- If you use partners for prep/shipping, ensure the specialist’s deliverables include handoff artifacts and version control.

If your operation involves multiple China suppliers, consolidation, labeling, and shipping into Amazon FBA, FBABEE supports sellers with China-side warehousing, prep, and door-to-door freight—so your ops specialist can coordinate clean handoffs instead of firefighting. Learn more at https://fbabee.com