The world of e-commerce is a hyper-competitive arena, and for Amazon sellers leveraging the Fulfillment by Amazon (FBA) model, logistics is the critical differentiator between moderate success and exponential growth. While FBA streamlines order fulfillment, the responsibility of efficiently moving inventory from manufacturer to Amazon’s fulfillment centers rests squarely on the seller. Mastering this supply chain, often called ‘pre-FBA’ logistics, is paramount for maintaining inventory health, controlling costs, and ensuring customer satisfaction.

This post delves into actionable strategies for optimizing your Amazon FBA logistics, enabling your e-commerce business to scale effectively and profitably.

1. The Imperative of Demand Forecasting and Inventory Planning

The foundation of sound logistics is accurate inventory planning. Overstocking leads to high storage fees and potential long-term storage penalties, while understocking results in missed sales, stock-outs, and a drop in search ranking. For FBA sellers, poor planning can also incur costly rush shipping to correct a sudden inventory shortfall.

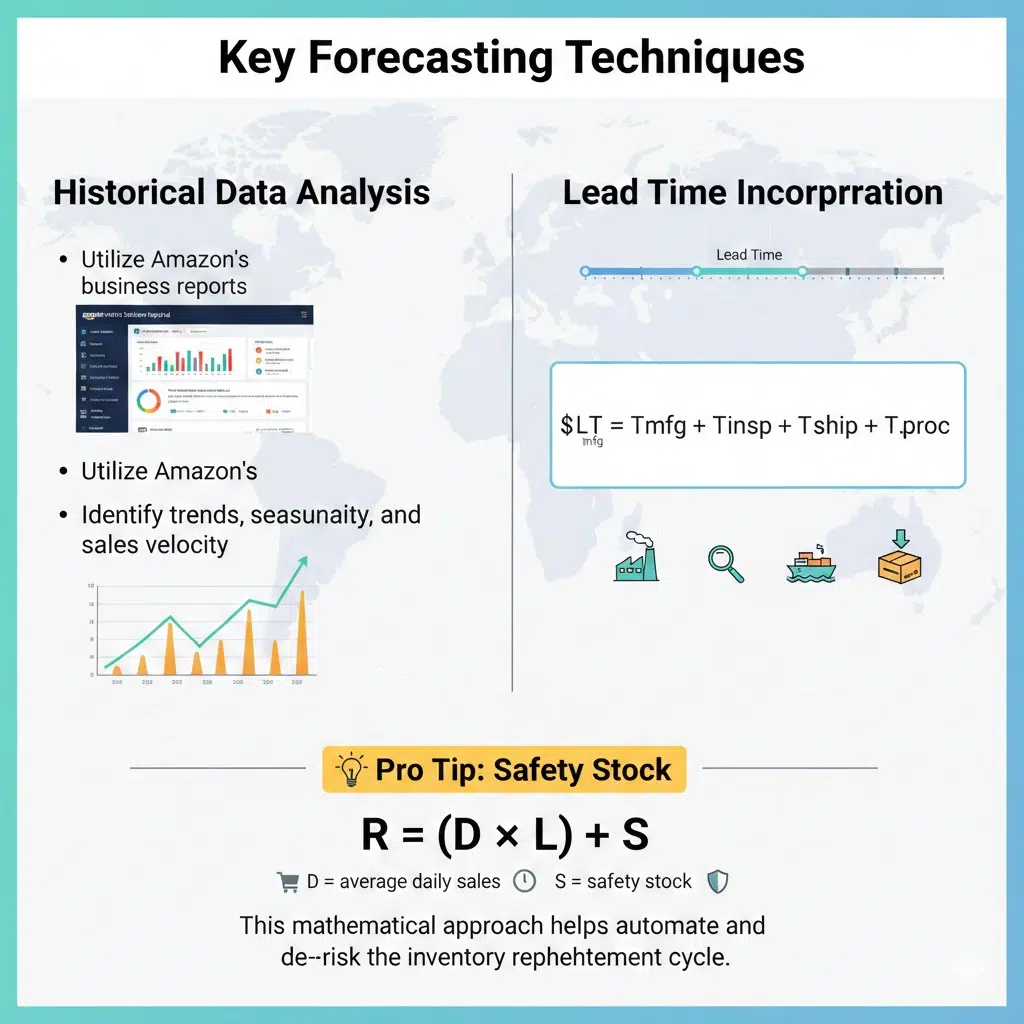

Key Forecasting Techniques:

- Historical Data Analysis: Utilize Amazon’s business reports and your sales data to identify trends, seasonality, and weekly/monthly sales velocity for each SKU. This data provides the backbone for predictive modeling.

- Competitor Analysis and Market Trends: Don’t just look inward. Monitor the sales ranking of your top competitors and analyze broader market trends (e.g., social media virality, changes in consumer behavior) that could influence future demand.

- Promotional Planning: Integrate planned promotions (e.g., Prime Day, seasonal sales, lightning deals) into your forecast. These events will temporarily inflate your sales velocity ($D$) and must be accounted for to prevent stock-outs during critical revenue periods.

Lead Time Incorporation: The Scale Equation

Accurately calculating the Total Lead Time ($T_{LT}$) is the most critical step in avoiding costly surprises. This is the time required from deciding to place an order to the product being available for sale on Amazon.

$$T_{LT} = T_{mfg} + T_{insp} + T_{ship} + T_{proc}$$

Where:

- $T_{mfg}$ (Manufacturing Time)

- $T_{insp}$ (Inspection/Preparation Time)

- $T_{ship}$ (Shipping/Transit Time)

- $T_{proc}$ (Amazon FC Processing Time)

Pro Tip: Always build a “Safety Stock” buffer into your planning to account for unexpected delays in the supply chain (e.g., customs holds, port congestion, quality control issues). A common and robust calculation for the Reorder Point ($R$) is:

$$R = (D \times L) + S$$

Where $D$ is the average daily sales, $L$ is the lead time, and $S$ is the safety stock. This mathematical approach helps automate and de-risk the inventory replenishment cycle, ensuring you initiate a new order just as your on-hand stock is projected to hit the safety stock level.

2. Strategic Sourcing and Vetting Logistics Partners

The sheer volume and geographical complexity of shipping goods to Amazon FCs necessitates reliable partnerships. The choice between air freight, ocean freight, or multimodal options dramatically impacts speed and cost.

Freight Modalities: Cost vs. Speed

- Ocean Freight (LCL/FCL): Most cost-effective for large, heavy, or high-volume shipments. Ideal for replenishing consistent sellers. Requires longer lead times (typically 30–45+ days). Less than Container Load (LCL) is suitable for smaller volumes, while Full Container Load (FCL) offers better per-unit pricing and a dedicated, faster transit path.

- Air Freight: Faster (5–10 days), but significantly more expensive. Best used for high-value, small items, or urgent inventory top-ups to prevent a stock-out. Use this strategically to maintain your BSR (Best Seller Rank) until your bulk ocean shipment arrives.

- Multimodal Shipping: Utilizing a combination of ocean freight for the main leg and then domestic truck/rail for the final mile. This can optimize cost while maintaining a reasonable speed.

Freight Forwarders: The Supply Chain Architects

A Freight Forwarder is a crucial partner that manages the complexities of international shipping, customs brokerage, and coordinating the final mile delivery to the Amazon FC. Vet them based on their expertise and experience with Amazon’s strict receiving requirements.

Due Diligence Checklist for Freight Forwarders:

- Experience with the specific country of origin (e.g., China, India, Vietnam) and the destination country’s customs regulations.

- Understanding of Amazon’s booking and labeling requirements (specifically the Carrier Appointment Request Portal – CARP). They must be adept at generating and managing the necessary Bill of Lading (BOL).

- Ability to handle Delivered Duty Paid (DDP) terms. This is a non-negotiable requirement for most seamless Amazon FBA shipments. DDP means the seller (you) is responsible for all import duties, taxes, and customs clearance fees. If this isn’t handled correctly, Amazon will refuse the shipment, resulting in massive delays and unexpected fees.

- Proof of Insurance/Cargo Coverage: Ensure they provide comprehensive cargo insurance to protect against loss or damage during transit.

3. Mastering Amazon’s Prep and Labeling Requirements

Amazon’s operational efficiency relies on highly standardized processes. Any deviation in product prep, labeling, or pallet configuration will lead to delays, rejection, chargebacks, or costly inbound service fees.

Critical Prep Steps:

- FNSKU Labels: The Digital Fingerprint

- Each sellable unit must have a scannable Amazon FNSKU label (e.g., X00-XXXXXX).

- This label links the physical product to your specific seller account and listing.

- Crucially, this label must cover or supersede any existing manufacturer barcodes (UPC/EAN) to prevent inventory errors and misidentification in the fulfillment centers. A single unit can only have one scannable barcode.

- Bundling/Kitting: If selling products as a set, they must be pre-packaged together and clearly marked as a set (e.g., “Ready to Ship,” “Do Not Separate”). If they are shipped loose, Amazon will inventory them as individual units.

- Protection and Safety: Fragile items require adequate bubble wrap, poly-bagging, or cushioning. Poly-bags must include a suffocation warning if the opening is greater than 5 inches, which is an easily overlooked but mandatory safety requirement.

- Box Content Information (BPI): Providing accurate BPI during the shipment creation workflow is critical. This tells Amazon exactly which units are in which box, speeding up the receiving process and avoiding manual processing fees.

The Shipping Labeling Trap

The most common point of failure for new sellers is the Shipping Box Labeling. Every carton/pallet must display the correct Amazon Shipping Labels (generated during the shipment creation workflow) clearly visible on the outside. Failure to affix these correctly will halt the receiving process, delay your inventory check-in, and can lead to penalties. The labels contain routing information that directs your shipment to the correct warehouse dock.

4. Leveraging Technology and Buffer Warehousing: The FBABEE Strategy

Manual tracking of inventory across disparate spreadsheets is unsustainable as your business scales. Modern e-commerce necessitates integrated tools and sophisticated storage solutions.

Inventory Management Systems (IMS)

These systems automate tracking stock levels, forecasting reorder points, and connecting sales data directly to your logistics pipeline. They provide a unified, real-time view of stock at the supplier, in transit, at Amazon FCs, and at 3PL warehouses. Key features include:

- Reorder Automation: Automatically calculates the reorder point ($R$) based on your defined parameters.

- Multi-Channel Synchronization: Manages inventory across Amazon, Shopify, eBay, etc.

- Profitability Analysis: Tracks logistics costs down to the SKU level for true Gross Margin analysis.

The FBABEE (Fulfillment by Amazon, But Even Easier) Approach

This is where a strategic buffer—often facilitated by a dedicated 3rd Party Logistics (3PL) provider—comes into play, forming the core of the FBABEE concept.

While FBA is the primary fulfillment method, utilizing a 3PL for overflow storage, consolidation, inspection, or to act as a buffer warehouse before sending inventory to Amazon can be a highly effective strategy.

The Power of the FBABEE Buffer:

- Cost Mitigation: Allows you to ship larger, more cost-effective quantities (e.g., FCL ocean freight) from your manufacturer. Instead of sending all of it to Amazon immediately and incurring high FBA storage fees (especially during peak season), the 3PL stores the bulk inventory at a significantly lower rate.

- Inventory Drip-Feeding: You can then “drip-feed” inventory into Amazon as needed, sending smaller, more manageable LTL or SPD shipments only when Amazon’s recommended stock levels require it. This minimizes exposure to Amazon’s punitive long-term storage and high-volume fees.

- Quality Control and Prep Hub: The 3PL serves as a final checkpoint for receiving, inspection, and performing any last-minute labeling or kitting services before the inventory is checked into the Amazon FC. This ensures Amazon’s requirements are met flawlessly, reducing expensive chargebacks and receiving delays.

- Mitigating Receiving Limits: Amazon frequently imposes restock limits on sellers. A 3PL buffer ensures your scale isn’t capped by Amazon’s fluctuating storage space availability. You maintain operational agility regardless of Amazon’s current capacity.

This FBABEE strategy is the hallmark of a mature, scalable e-commerce operation—it separates bulk cost efficiency from Amazon’s restrictive, high-cost storage model.

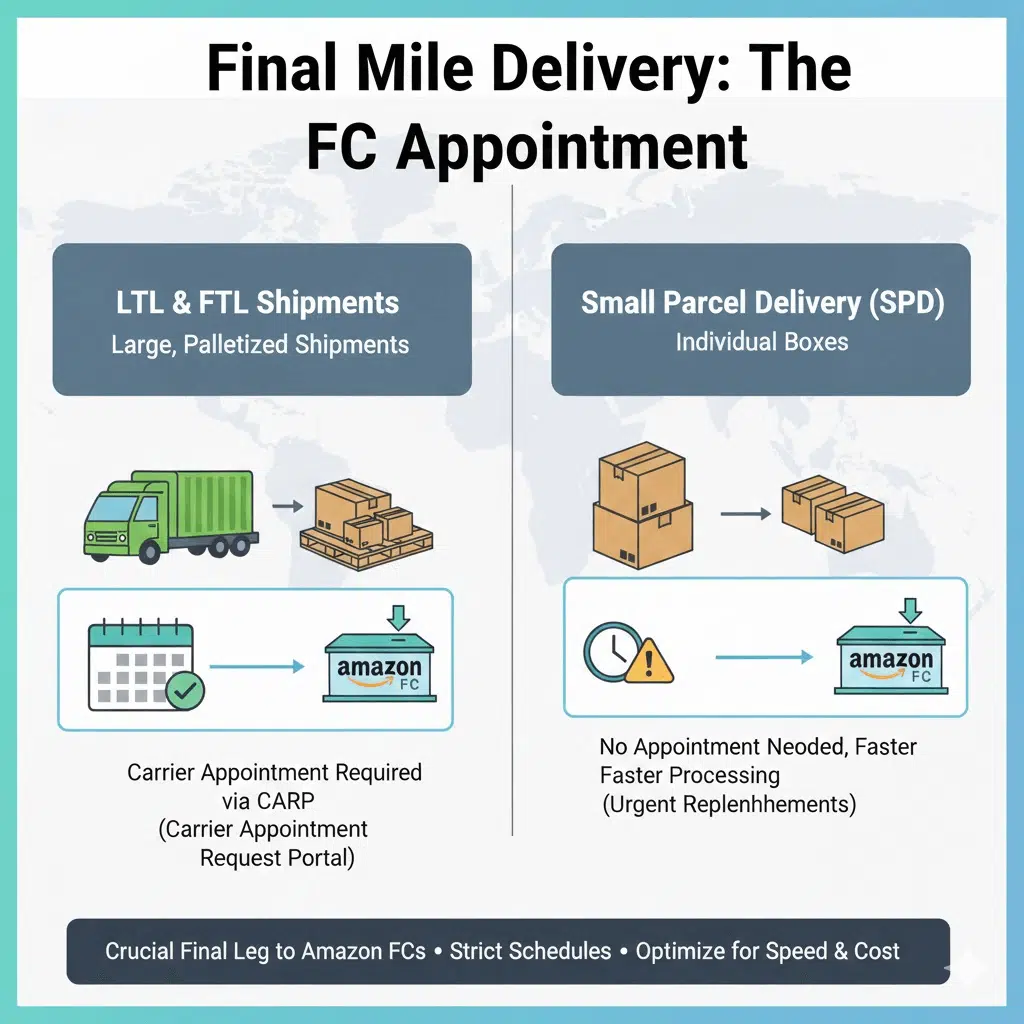

5. Final Mile Delivery: The FC Appointment

The final and crucial leg of the journey is the delivery to the Amazon Fulfillment Center (FC). This is where coordination with your freight forwarder or 3PL becomes paramount.

Less Than Truckload (LTL) & Full Truckload (FTL)

These larger, palletized shipments must have a delivery appointment time slot successfully booked by the carrier via the Carrier Appointment Request Portal (CARP).

- The Bottleneck: This step is a common bottleneck, especially during Q4 (peak season), and requires constant, proactive coordination between your carrier and the Amazon FC. Carriers must have the correct Amazon Reference Number and PO ready to secure and keep their slot.

- The Pallet Requirement: Pallets must adhere to strict dimensions (typically 40″ x 48″) and be stretch-wrapped, clearly labeled on all four sides, and include the correct Pallet Labels generated in the shipment workflow.

Small Parcel Delivery (SPD)

Shipments of individual boxes (usually via UPS/FedEx) do not require an appointment and are generally processed quicker, making them ideal for smaller, urgent replenishments. The key is ensuring the weight and dimension limits are adhered to, and every box has the necessary Amazon shipping and content labels.

Conclusion

For a growing Amazon FBA business, logistics is not merely a cost center; it is a strategic asset. By employing rigorous demand forecasting, vetting reliable logistics partners who specialize in Amazon DDP shipments, and flawlessly adhering to Amazon’s prep and labeling guidelines, sellers can build a robust, predictable, and scalable supply chain.

The adoption of the FBABEE strategy—leveraging a strategic 3PL buffer to manage inventory bulk, mitigate storage fees, and maintain a constant, controlled flow of stock into Amazon—is the key to unlocking true scaling potential.

Optimized logistics lead directly to lower operational costs, fewer stock-outs, and a healthier Seller Central account, paving the way for sustained success in the competitive e-commerce landscape. Focus on these areas, and your business will be well-positioned to handle significant volume growth without supply chain collapse.

Need Expert E-commerce Logistics Support?

Contact the FBABEE Consulting Team: EHPconsulting@fbabee.com

Email: info@ehpconsultinggroup.com

Website: www.ehpconsultinggroup.com

Phone: 925-293-3313

Date: November 20, 2025