Fast Answer: The difference between Amazon FBA and FBM (in one sentence)

Direct answer: FBA means Amazon stores your inventory and handles pick/pack/ship (and much of the customer-facing fulfillment work). FBM means you (or your 3PL) store inventory and ship orders yourself, so you own day-to-day fulfillment operations.

Reference for definitions and program framing: https://sell.amazon.com/blog/fba-vs-fbm

Key points (micro-bullets)

- Storage: FBA = Amazon warehouses; FBM = your warehouse/3PL.

- Shipping: FBA = Amazon fulfills orders; FBM = you/3PL buy labels and ship.

- Customer service & returns: FBA generally reduces your fulfillment workload; FBM requires your own processes.

- Control: FBM usually gives more hands-on control over packaging/handling; FBA outsources more execution.

Boundary conditions

- “FBM” can be in-house or run through a third-party logistics provider (3PL).

- Exact workflows and program details can vary by category and marketplace—use Amazon’s current guidance for specifics.

Next question prompt: Are you trying to optimize for time and simplicity, or control and fulfillment flexibility?

Definitions: What is Amazon FBA? What is Amazon FBM (and MFN)?

Direct answer: Amazon uses “FBA” and “FBM” to describe who fulfills orders—Amazon (FBA) or the merchant (FBM).

Helpful official baseline pages:

- FBA overview: https://sell.amazon.com/fulfillment-by-amazon

- FBM overview: https://sell.amazon.com/programs/fulfilled-by-merchant

Key definitions

- FBA (Fulfillment by Amazon): You send inventory to Amazon; Amazon stores it and fulfills customer orders from their network.

- FBM (Fulfilled by Merchant): You (or your 3PL) store inventory and ship orders directly to customers.

- MFN (Merchant Fulfilled Network): Often used as another way to refer to merchant-fulfilled selling (commonly aligned with FBM terminology).

Boundary conditions

- Some articles use “MFN” and “FBM” interchangeably; when in doubt, follow Amazon’s definitions in Seller Central and official program pages.

Next question prompt: Which part feels harder for you right now—shipping operations or getting inventory positioned and in stock?

Who does what: FBA vs FBM responsibilities (side-by-side table)

Direct answer: The core difference is task ownership: FBA outsources more fulfillment execution to Amazon, while FBM keeps the seller (or a 3PL) responsible for the fulfillment workflow.

Reference framing: https://sell.amazon.com/blog/fba-vs-fbm

Why this matters: Responsibilities drive cost drivers, workload, and how predictable your operations feel day to day.

Responsibilities table

| Fulfillment task | FBA (Fulfilled by Amazon) | FBM (Fulfilled by Merchant / MFN) |

|---|---|---|

| Inventory storage | Stored in Amazon’s network | Stored in your warehouse or 3PL |

| Pick/pack/ship | Amazon handles fulfillment steps | You/3PL pick, pack, label, and ship |

| Shipping label purchasing | Typically managed within Amazon’s fulfillment system | You/3PL choose carriers, rates, and ship methods |

| Customer-facing delivery experience | Often aligns with Amazon network expectations | Depends on your shipping speed, cutoffs, and carrier performance |

| Customer messages (fulfillment-related) | Reduced operational load (varies by situation) | You handle shipping questions, address changes, and delivery issues |

| Returns handling | Amazon handles many steps (varies by situation) | You manage returns routing, inspection, restock/disposal decisions |

| Inventory planning touchpoints | Replenishment into Amazon + receiving constraints | Inventory placement across your warehouse/3PL + carrier planning |

What sellers still always own (both models)

- Listing quality, pricing strategy, inventory decisions, and product compliance.

- Customer experience decisions (policies, brand presentation) within Amazon’s rules.

Boundary conditions

- In FBM, your reality depends heavily on whether you fulfill in-house or via a 3PL.

- Program rules and operational details can change; treat official Amazon pages as the baseline.

Next question prompt: Do you already have a reliable warehouse/3PL and shipping process—or would you be building that from scratch?

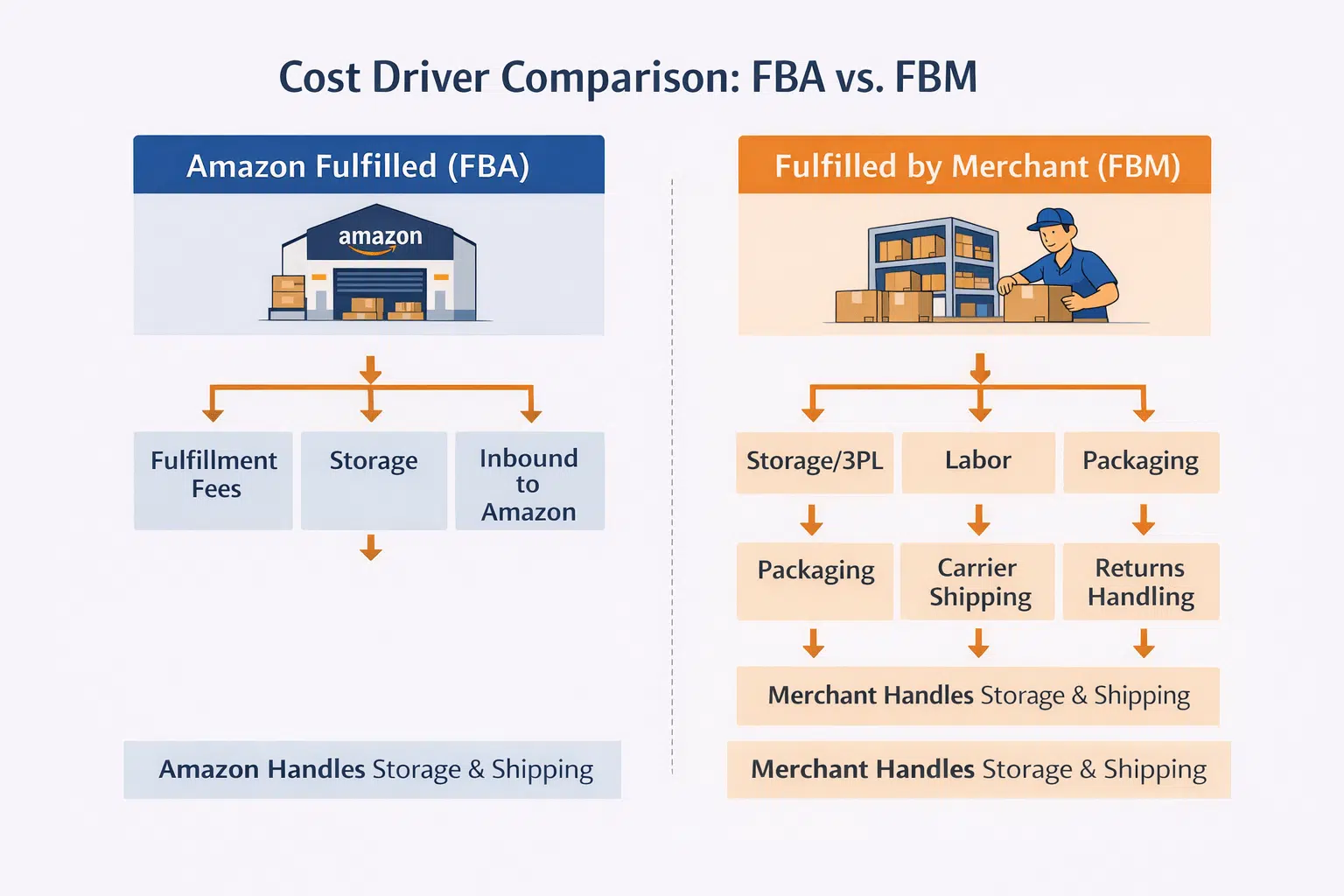

Cost differences: the driver model (and where to verify current fees)

Key cost drivers (no stale numbers)

- FBA tends to concentrate costs in: fulfillment-related fees, storage-related fees, inbound shipping and prep/compliance to send inventory into Amazon.

- FBM tends to concentrate costs in: warehouse/3PL storage and handling, labor and packing materials, carrier shipping charges, returns processing and restocking decisions.

Cost driver mini-table

| Cost driver | FBA (typical pattern) | FBM (typical pattern) |

|---|---|---|

| Storage | You pay Amazon for storage services | You pay your warehouse/3PL (or your own space) |

| Fulfillment labor | Mostly outsourced into Amazon fees | You/3PL pay labor to pick/pack/ship |

| Shipping | Often embedded in the fulfillment service model | You/3PL pay carriers per shipment |

| Packaging | Must meet Amazon requirements; prep may be needed | You choose materials and SOPs; brand control may be higher |

| Returns | Many steps can be handled through Amazon processes | You manage routing, inspection, and restock decisions |

Where to verify current fees (without copying tables)

- Start at Amazon’s pricing/fees hub and follow through to the current documentation and calculators: https://sell.amazon.com/pricing

- Use Seller Central’s tools and current fee documentation for the most accurate, up-to-date rates (fees can change).

- When comparing FBM, verify your carrier rates, packaging costs, labor, and 3PL pricing (if applicable).

Boundary conditions

- Total cost depends on product size/weight, destination, seasonality, return rate, carrier pricing, and current fee schedules.

- Avoid deciding on a single fee line—use a total “fulfillment cost per order” view for your SKU.

Next question prompt: For your products, which is more uncertain right now—Amazon fee impact or your shipping/3PL execution costs?

Which is better (and more profitable): FBA vs FBM depends on your situation

Direct answer: There’s no universal “better.” FBA often wins on time savings and outsourced operations; FBM often wins on control and fulfillment flexibility. Profitability depends on your cost drivers and how well you execute fulfillment.

Define what “better” means for you

- Profit: total fulfillment cost vs margin

- Time: how much operational work you can handle

- Control: packaging, inserts, multi-channel fulfillment, special handling

- Customer experience: delivery expectations and returns experience

- Scalability: ability to handle spikes without breaking SOPs

When FBA tends to fit

- You want to reduce day-to-day fulfillment workload.

- You have consistent demand and can replenish inventory into Amazon regularly.

- You prefer a simpler operating model than managing carriers/warehouse daily.

- Your team capacity is limited and you’d rather outsource fulfillment execution.

When FBM tends to fit

- You want tighter control over packaging, bundling, or special handling.

- You have strong shipping/warehouse capability (in-house or a reliable 3PL).

- You plan to fulfill multi-channel (Amazon + DTC) from the same inventory pool.

- You can manage shipping SLAs and customer support consistently.

Quick chooser table (decision grid)

| If your priority is… | FBA often fits when… | FBM often fits when… |

|---|---|---|

| Saving time | You want Amazon to execute fulfillment | You can run or outsource shipping reliably |

| Maximizing control | You accept less packaging control | You need custom packaging/SOPs |

| Cost predictability | You prefer an Amazon fee-based structure | You have stable carrier/3PL costs and strong ops |

| Flexibility | You’re okay with inbound + network constraints | You want to route inventory across channels/locations |

Decision checklist (answer “yes/no”)

- Can you reliably ship orders same/next day with clear cutoffs (or have a 3PL that can)?

- Do you have warehouse space (or 3PL capacity) to store inventory and manage returns?

- Is packaging control (branding/inserts/special handling) a key requirement?

- Do you plan to fulfill other channels from the same inventory?

- Are your carrier rates competitive and stable enough to forecast?

- Can you handle customer messages and return workflows consistently?

- Is your main constraint time/ops bandwidth (push toward outsourcing) or flexibility/control (push toward merchant fulfillment)?

Boundary conditions

- Avoid assuming “more profitable” without testing—profitability depends on total cost and execution quality.

- Don’t assume Prime outcomes or Buy Box outcomes; those are influenced by multiple factors and can change.

- For many catalogs, the “best” answer is often hybrid per SKU (see next section).

Next question prompt: Which single constraint is most limiting right now—cash tied in inventory, time to fulfill, or shipping performance consistency?

Prime, delivery expectations, and Seller Fulfilled Prime (SFP)

Direct answer: FBA is often aligned with delivery expectations because fulfillment runs through Amazon’s network. With FBM, customer experience depends on your shipping speed, cutoffs, carrier reliability, and returns/customer support processes.

Key points

- FBA: often reduces fulfillment complexity and supports consistent delivery operations through Amazon’s fulfillment network.

- FBM: can work well when you have strong shipping execution and clear support/returns processes.

- SFP: an adjacent program concept where sellers fulfill orders while meeting Prime shipping standards; requirements can change, so treat it as “check current rules,” not a guarantee.

What changes the answer

- Your ship-from locations and carrier performance.

- Your ability to maintain consistent cutoffs, tracking, and on-time delivery.

- Current program requirements and eligibility rules.

Boundary conditions

- Don’t promise Prime eligibility; verify current requirements in Seller Central and official program documentation.

Next question prompt: Do you have the operational setup to consistently meet strict shipping performance targets if you choose FBM?

Workload and control: what you outsource vs what you manage

Direct answer: FBA typically outsources more day-to-day fulfillment work to Amazon. FBM typically increases operational control—but also increases the work you (or your 3PL) must manage to hit shipping and customer experience expectations.

Trade-off table

| Dimension | FBA (typical pattern) | FBM (typical pattern) |

|---|---|---|

| Daily fulfillment labor | Lower for the seller | Higher unless 3PL handles it |

| Packaging/control | More standardized; less hands-on control | More flexibility for SOPs and brand needs |

| Returns workflow | Many steps handled through Amazon processes | You must build/manage returns SOPs |

| Customer service load (fulfillment-related) | Often reduced | You manage shipping issues and returns communication |

| Operational complexity | Inbound + replenishment planning | Warehouse/3PL ops + carrier + returns ops |

Minimum setup checklist for FBM (practical reality)

- Shipping cutoffs and carrier pickup plan

- Standard packing SOPs and materials

- A returns SOP (where returns go, inspection steps, restock/disposal rules)

- Customer support coverage for delivery and return issues

- Inventory visibility (to prevent overselling and stockouts)

Boundary conditions

- FBM workload varies hugely depending on whether you use a 3PL and how automated your shipping process is.

- Hybrid strategies can reduce risk but add planning complexity.

Next question prompt: If you switched to FBM tomorrow, which SOP is weakest—shipping, returns, or customer support coverage?

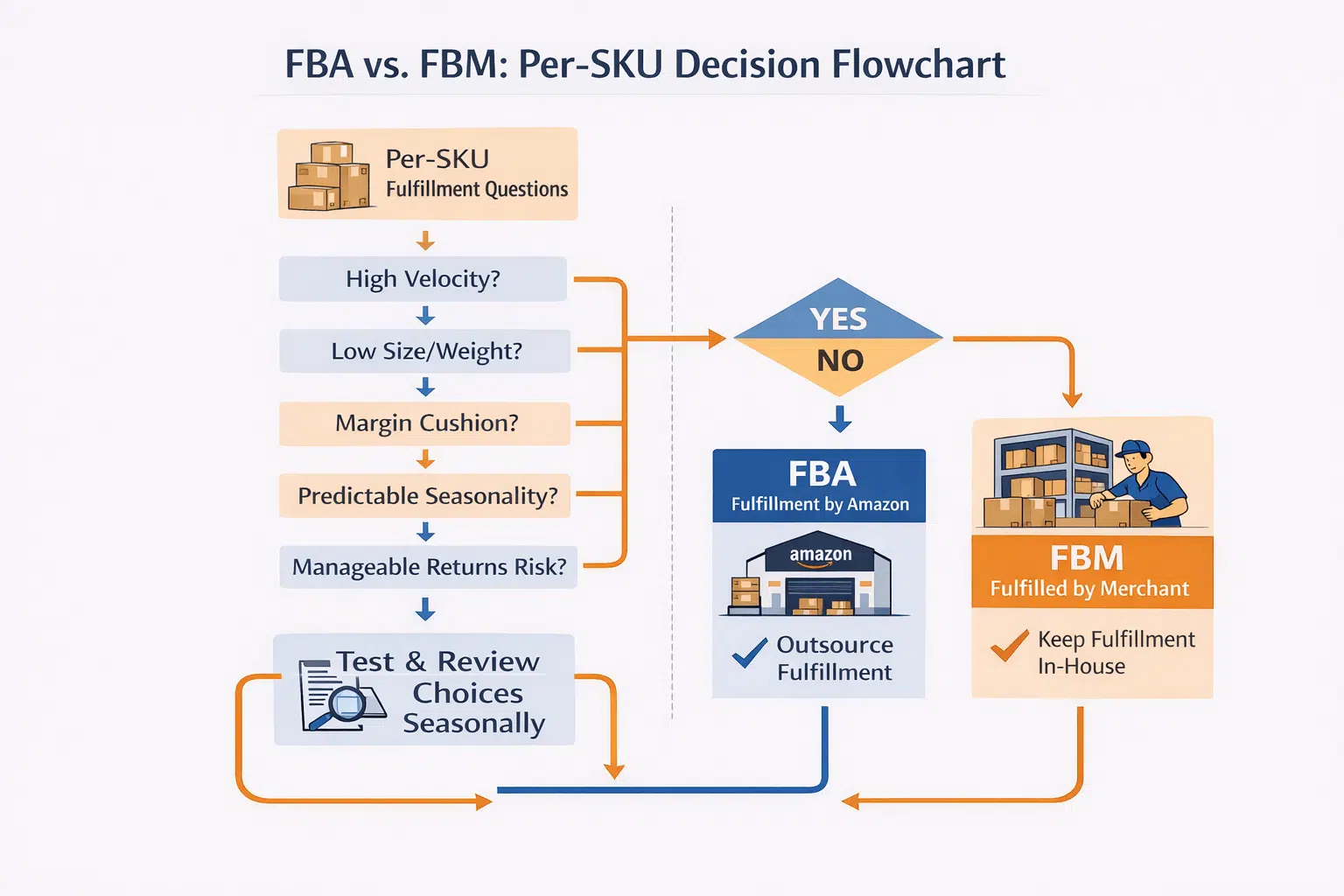

Hybrid strategy: use FBA and FBM together (how to decide per SKU)

Direct answer: Yes—many sellers run a hybrid approach, using FBA for some SKUs and FBM for others. The key is choosing a “default method” per SKU based on velocity, handling needs, and fulfillment constraints.

Per-SKU steps (5–7)

- Segment SKUs by velocity, size/weight, margin cushion, and seasonality.

- Mark constraint SKUs (special packaging, fragile items, high returns, oversized shipping complexity).

- Pick a default method per SKU: FBA where outsourcing helps; FBM where control/flexibility wins.

- Plan inventory splits (if needed): where each SKU will be stored (Amazon vs warehouse/3PL).

- Set replenishment triggers to avoid stockouts and avoid over-splitting inventory.

- Pilot and measure: compare cost drivers and operational effort.

- Review seasonally and adjust.

Optional SKU segmentation table

| SKU profile | Often a good first test for… | Why |

|---|---|---|

| High-velocity, predictable demand | FBA | Outsourcing reduces daily ops burden and helps consistency |

| Needs custom packaging/inserts | FBM | More control over SOPs and brand presentation |

| Highly seasonal | Hybrid | Flex between methods as demand changes |

| High returns complexity | Either (test) | Choose based on where your returns SOP is strongest |

Watch-outs (hybrid complexity)

- Inventory fragmentation can cause stockouts even when you have stock “somewhere.”

- Forecasting mistakes can create unnecessary storage or shipping pressure.

- Switching methods requires SOP changes (returns routing, customer comms, packaging).

- Managing both FBA inbound and FBM ops increases planning overhead.

Boundary conditions

- Hybrid may not be worth it for very small catalogs; start simple and expand only if it adds value.

Next question prompt: Which SKUs are the most risky operationally—oversize, fragile, high-return, or highly seasonal?

Common mistakes when switching between FBA and FBM (and how to fix them)

Direct answer: Most switching failures come from underestimating operations—shipping cutoffs, inventory planning, and returns/customer support—plus using stale assumptions about fees or shipping rates.

Mistakes checklist (avoid these)

- Switching to FBM without clear shipping cutoffs and carrier pickup reliability.

- Underestimating packing labor and packaging material costs in FBM.

- No returns SOP (where returns go, inspection, restock rules).

- Weak customer support coverage for delivery exceptions and return questions.

- Splitting inventory across FBA and FBM without a replenishment plan (stockouts).

- Comparing FBA vs FBM using outdated fees or outdated carrier rates.

- Onboarding a 3PL without clear SLAs, labeling rules, and exception handling.

- Changing fulfillment method without updating SOPs and operational expectations.

If/then fixes (practical)

- If FBM shipments run late, then set earlier cutoffs, automate label buying, and confirm daily carrier pickup.

- If FBM packing time is too high, then standardize packaging SOPs and pre-kit materials.

- If returns overwhelm your team, then create a returns triage SOP and reconsider which SKUs should be fulfilled differently.

- If FBA costs surprise you, then re-check current fee documentation and re-evaluate which SKUs belong in FBA vs FBM.

- If hybrid causes stockouts, then reduce inventory splitting and set replenishment triggers before expanding hybrid scope.

- If 3PL execution is inconsistent, then tighten SLAs and limit 3PL to a smaller SKU set until stable.

Boundary conditions

- Switching is an operational transition; plan SOPs and monitoring instead of a one-time “flip.”

- Fees and rates change; always verify current info in Seller Central and with carriers/3PLs.

Next question prompt: What’s your biggest switching risk—late shipments, inventory stockouts, or returns handling?

FAQ

- Q: What is the main difference between Amazon FBA and FBM?

A: FBA means Amazon stores and fulfills orders for you; FBM means you (or a 3PL) store inventory and ship orders yourself. The difference is who owns fulfillment execution day to day. https://sell.amazon.com/blog/fba-vs-fbm - Q: What is Amazon FBA and what is Amazon FBM (and is FBM the same as MFN)?

A: FBA is “Fulfillment by Amazon” (you send inventory to Amazon; Amazon fulfills). FBM is “Fulfilled by Merchant” (you/3PL fulfill). MFN is commonly used to describe merchant-fulfilled selling and is often aligned with FBM terminology. https://sell.amazon.com/fulfillment-by-amazon and https://sell.amazon.com/programs/fulfilled-by-merchant - Q: Which is better, FBA or FBM?

A: It depends on your constraints. FBA often reduces operational workload; FBM often increases control and flexibility. Many sellers choose per SKU and use a hybrid approach. - Q: Is Amazon FBM more profitable?

A: Sometimes, but not always. FBM can be more profitable when shipping/warehouse costs are optimized and execution is strong; FBA can be more profitable when outsourcing reduces labor/time and improves consistency. Compare total cost drivers per SKU rather than assuming one model wins universally. - Q: How much does Amazon FBM cost?

A: FBM costs vary and usually include your shipping labels, packaging, labor, and storage (plus any 3PL fees). Build a per-order cost model using your carrier rates and operational costs, then compare against current official fee documentation for FBA. Official fee entry point: https://sell.amazon.com/pricing - Q: Can you use FBA and FBM at the same time?

A: Yes. Many sellers use FBA for SKUs where outsourcing fulfillment saves time and improves consistency, and FBM for SKUs that need more control or different shipping economics. Use a per-SKU segmentation approach and set replenishment rules to avoid stockouts. - Q: What mistakes should you avoid when switching between FBA and FBM?

A: Underestimating FBM ops (cutoffs, returns SOPs, support coverage), relying on stale fee/rate assumptions, and splitting inventory without a replenishment plan are top mistakes. Pilot changes on a small SKU set first and add if/then fixes for common failures. - Q: Do I need an LLC to sell on Amazon FBM?

A: Not necessarily. Whether you need an LLC depends on your jurisdiction, risk tolerance, and tax/legal situation—not on whether you use FBM or FBA. Consider local guidance and professional advice (not legal advice).

Summary & Next Steps

Direct answer: FBA vs FBM is mainly about who fulfills (Amazon vs you/3PL). The best choice depends on your cost drivers, operational capacity, and SKU constraints—and many sellers end up using both.

Key takeaways

- Start with responsibilities: who stores, ships, handles returns, and supports customers.

- Compare costs by drivers, not stale numbers; verify current fees in Seller Central and official pricing pages.

- Decide by scenario and SKU profile; don’t assume one model is universally better.

- If switching, treat it as an operational transition with SOPs, cutoffs, and monitoring.

Next steps

- Pick 1–3 SKUs and run a simple driver-based comparison (FBA vs FBM total cost drivers + operational effort).

- If considering FBM, confirm your shipping SOP, returns SOP, and customer support coverage.

- If considering hybrid, define replenishment triggers to prevent stockouts from inventory splits.

Note: If you’re sourcing from China and planning FBA inbound shipments (or balancing FBA with a warehouse/3PL plan), FBABEE supports freight, consolidation, and FBA prep workflows so inventory arrives ready for inbound. Learn more at https://fbabee.com/

Boundary conditions

- Fees, programs, and requirements change; verify current details in Seller Central and official Amazon documentation.

- Don’t treat Prime/SFP outcomes as guaranteed; check current eligibility rules.

Next question prompt: What’s your current constraint—shipping operations, inventory planning, or cost predictability?